Spazio3D Optimization 1

Spazio3D Optimization 1 is a cutting optimizer for cutting machines, created to arrange the panels inside the panel sheets in the best way.

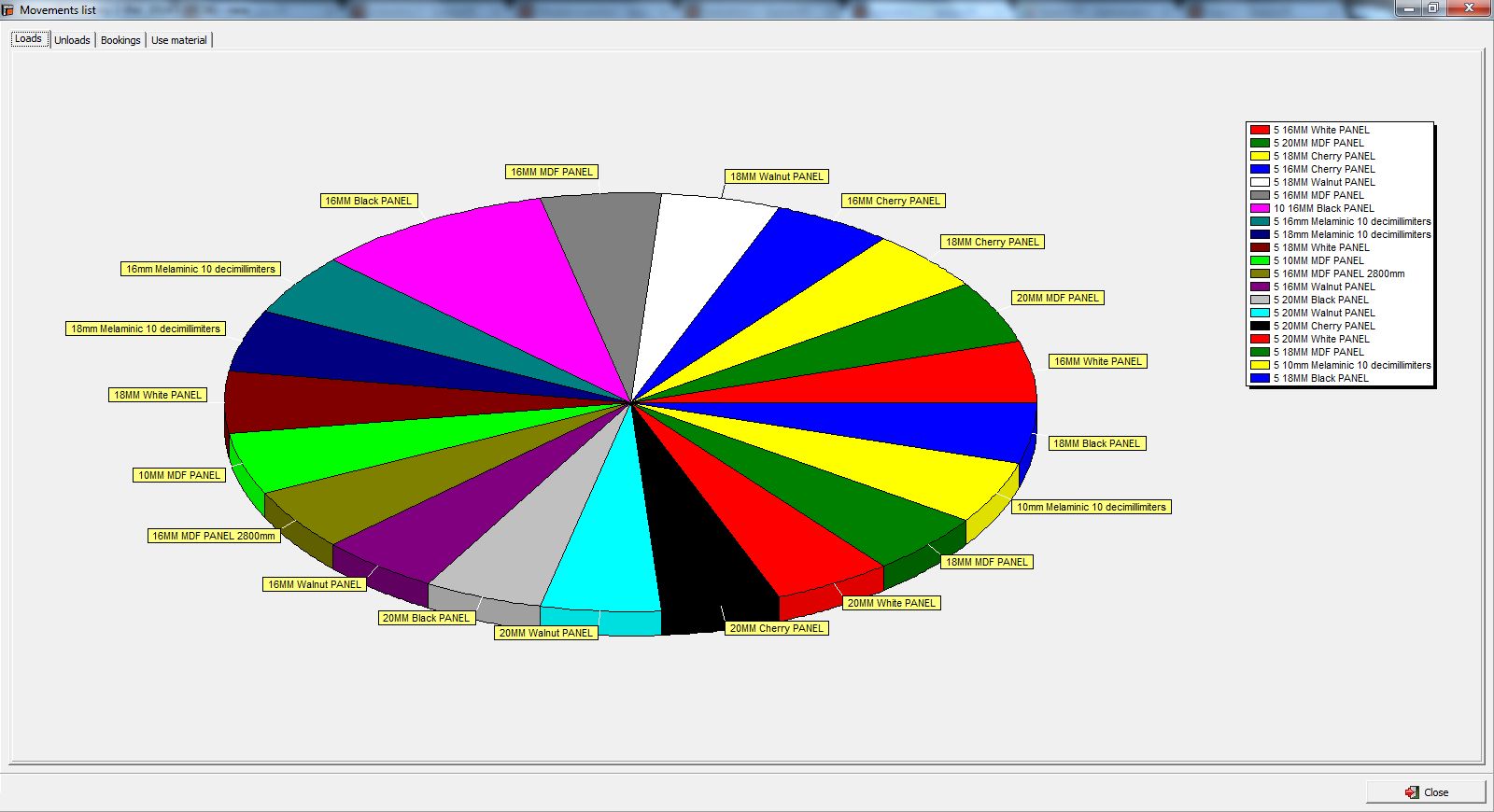

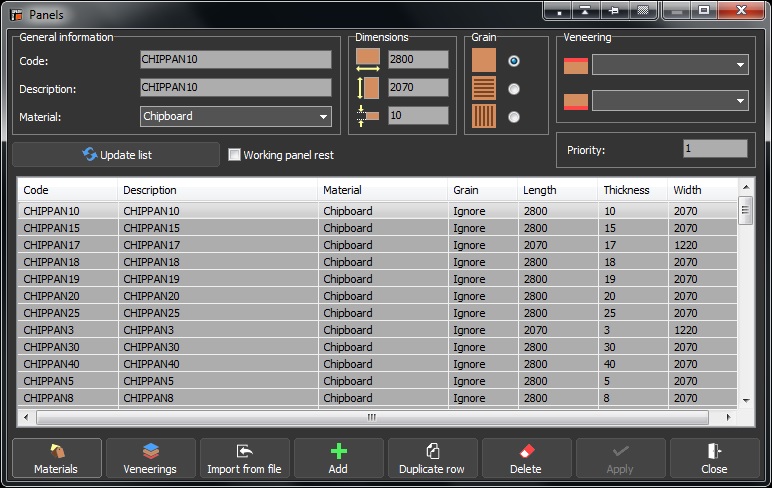

The various panels can be sorted by material, veneerings, thickness and grain direction.

The interface, very simple and intuitive, is very quick during the creation of the cutting list and in the eventual optimization report with automatic dimensioning.

The Optimization versions allows to create outputs for specific cutting machines.

Spazio3D Optimization 1 is compatible with all Spazio3D products, so it can open and elaborate files with ".s3d" extension.